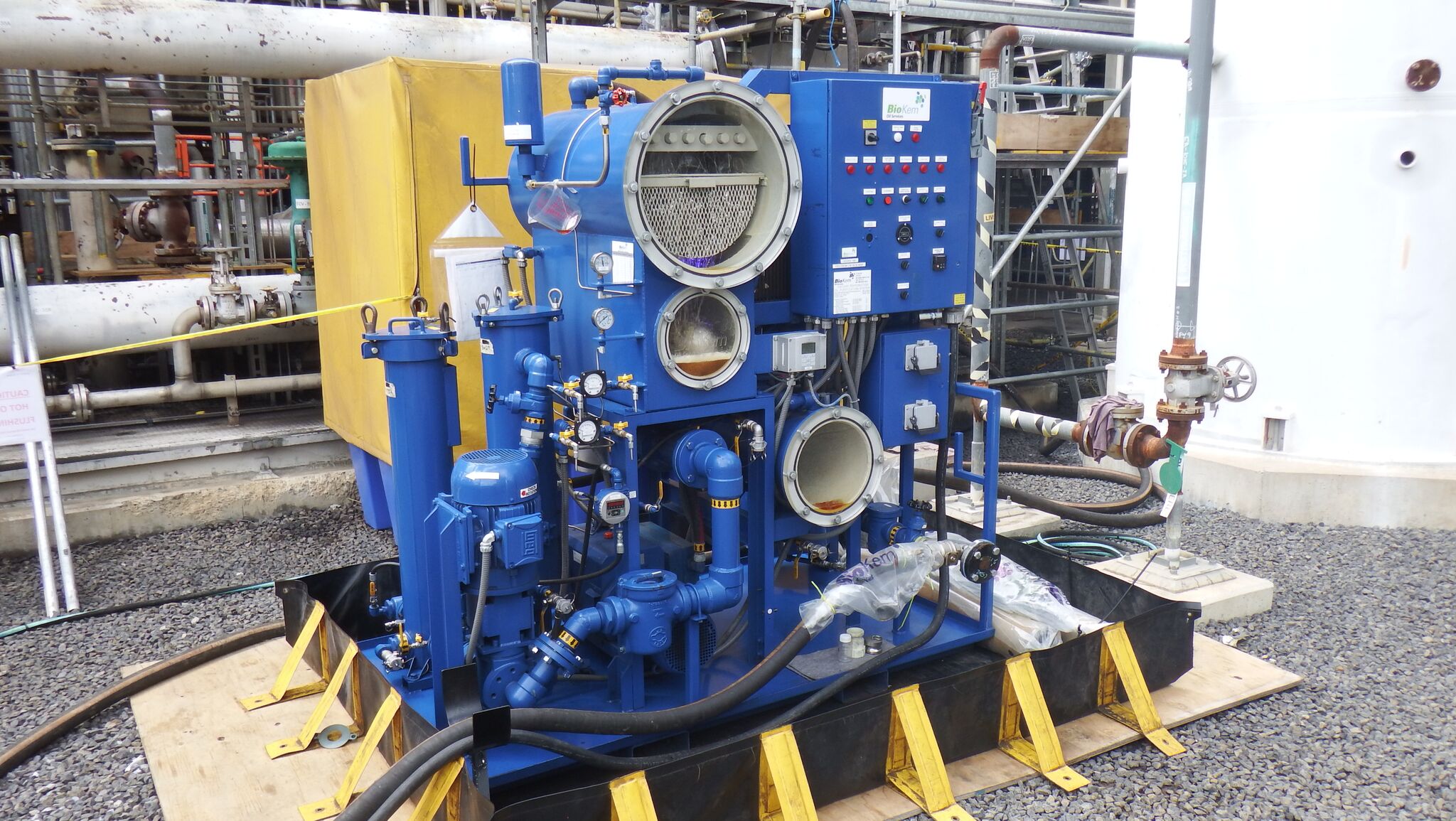

Vacuum Dehydrator Oil Purification Systems (Oil Purifier)

Description:

The harmful effects of particulate and moisture contamination in hydraulic and lubrication oils have been well documented. By maintaining absolute fluid cleanliness, end-users can dramatically increase the life of critical wear components on rotational equipment, minimizing downtime and maximizing profitability. OilQuip supplies the most effective, durable, and user-friendly vacuum dehydrators on the market today. Special engineered design features maximize the water extraction rates of our oil purifiers, and top-quality components and workmanship ensure years of maintenance-free operation and performance.Performance

- Flow Rates Range From: 20lpmto 190lpm or Higher.

- Water Removal: Achieve overall water content as low as 20 PPM In multi-pass by removing free, emulsified, and dissolved water.

- Particulate Removal: Achieve particle counts as low as ISO 14/12/9 with high efficiency pleated microglass filter elements rated Beta(c)>1000 per ISO 16889

- Entrained Air and Gas Removal: Degassing via Vacuum Distillation

- Acid Removal: Can Be Equipped With Fullers Earth or Activated Alumina Cartridges To Neutralize Acid and Lower TAN

- Varnish Removal: Can Be Equipped With Ion Charged Bonding Cartridges To Remove Insoluble Varnish

Standard Features

- Permanent Dispersion Media Inside Vacuum Tower - maximizes water extraction rates, eliminates the need for costly replacement of coalescer filter elements, and enables the system to operate effectively on high viscosity gear oils.

- Variable Frequency Drive enables operator to dial in the optimal flow rate, and enhances the system overall performance during cold start-ups, on higher viscosity oils, or when a restricted inlet condition exists.

- Claw-Style Vacuum Pump - pulls deeper vacuum, higher CFM, and requires much less maintenance than other conventional vacuum pumps.

- Single Utility - requires 480V, 3-Phase electric service only, not a chilled water supply.

- System View Windows - enables operator to observe system operation and performance.

- Plugged Filter Indicator Light - positive indication when the particulate removal filter element is plugged and needs to be changed.

- Safety Trips-Machine will switch off and isolate with low flow, plugged filters, high fluid level and service requirements.

Optional Features

- Automatic Water Drain

- Inline Digital Particle Monitor

- Inline Digital Moisture Indicator

- NEMA 7 Explosion Proof Components

- Stainless Steel Wetted Parts

- 4-Point Lifting Lug Cage Structure

Designed for use on

- Hydraulic Oil

- Turbine Oil

- Lubrication Oil

- Gear Oil (ISO VG 220 to ISO VG 680)

- Transformer Oil

- Diesel Fuel

- Phosphate Ester (Fyrquel EHC Fluid)

- PAO Fluid